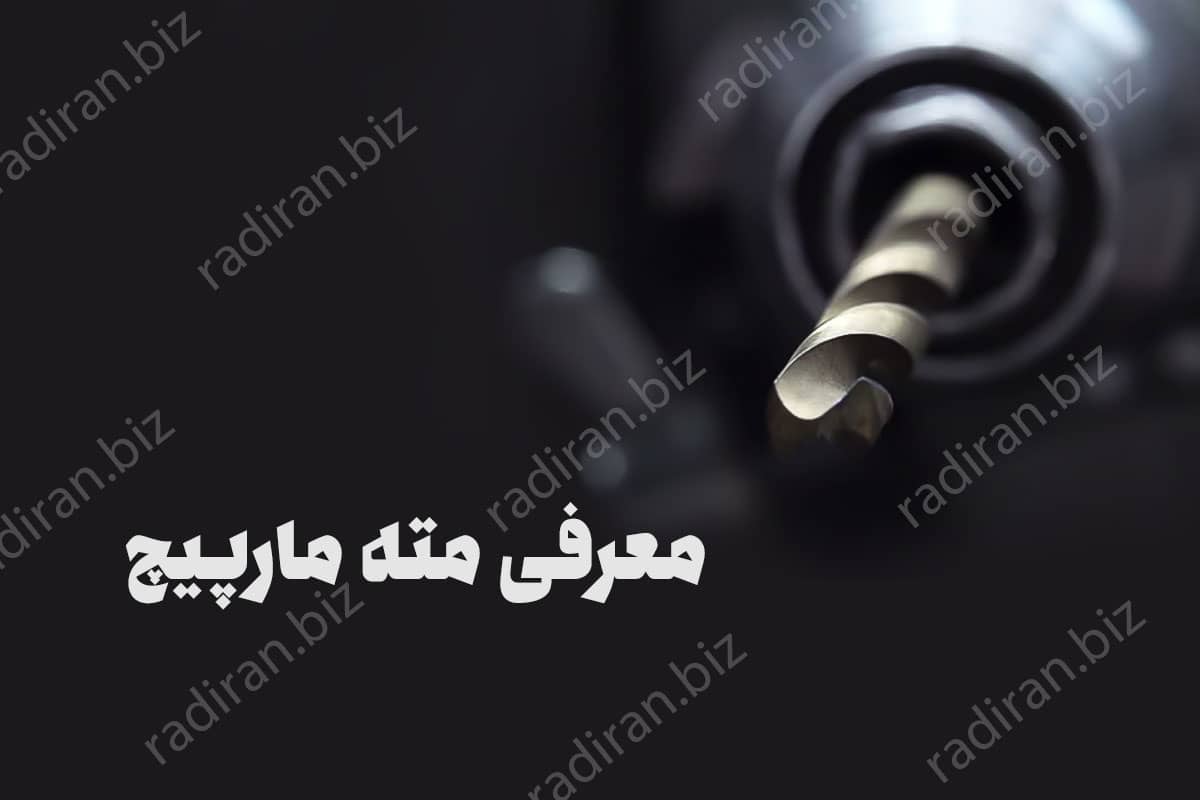

The spiral drill is one of the most important and routine drills in the work drill. To work with a drill, you need to get to know the types of drills so that you can use them better. A twist drill has grooves around and on the sides. The presence of these grooves shows the quality and properties of the drill. These grooves perform the drilling operation.

Introduction of twist drill

Why are these drills called twisting or spiral?

They are known by this name because there are spiral threads on the body of the drill. These threads are responsible for removing the chips from the surface. Also, the grooves are responsible for bringing air and coolants to the drill tip. These grooves are very important in better drilling performance, otherwise they would be made as unthreaded cylinders.

Professional tips for working with a twist drill

If you want to have professional work and accurate drilling, the most important factor is choosing a suitable and quality spiral drill. You should choose a drill for any device you want to drill according to its material. In the following, we will introduce you to the features of various types of spiral drills.

drill axis

If the axes are big and thick, they have more strength in thick metals and wood and perform the drilling operation better. The bigger the axis or the torque of the drill, the less the vibration. In order for the chips to come out better from inside the holes during drilling, the closer we get to the end of the drill, the thicker it gets.

Important points in using a twist drill

Drill tip angle

The angles of the edges of the drill meet at the tip of the drill. The angle of the drill tip is used to fix the spiral drill on the desired surface. The smaller the angle of the tip, the easier it is to fix the drill head on the work surface. If this angle is small, it also makes the main edges of the drill longer, which reduces the possibility of slipping on the desired surface. Spiral drills are one of the most used drills in the market. Due to the sharpness of the two ends of the drills, the chipping work is done easily.

This thin angle reduces the friction between the drill bit and the surface. With the drill tip, you can easily fix the drill and increase the quality of drilling. The angle of the drill bit has different shapes. We will get to know them later.

The shape of the drill tip

spiral tip

The tip of the gap

split tip

drill groove

Grooves are used to remove chips from drilling in wood and metals. If the size of the profiles are large and wide, the chipping is done better. Usually, wide grooves are suitable for drills with a large diameter and deep grooves for drills with a small diameter. The important thing to pay attention to is the complete removal of chips from the hole. If this work is not done completely, the temperature of the drill will increase and the possibility of breaking the drill will increase.

cutting edges

One of the most important parts in any drill that indicates better performance is the cutting edges of the spiral drill. The longer the cutting edges, the better the drilling is done. A twist drill has two edges that connect to the drill tip in its center.

Drill helix angle

Spiral angle

The helix angle determines how the chip is removed during drilling. The higher the spiral angle, the better the chips are removed. Drills with a short helix angle are used for drilling hard surfaces such as metals. These surfaces do not have many chips and work with small angle drills is suitable for them.

The size of the angle of the spiral drill

Drills with an angle of 10 to 19 degrees have a longer spiral band.

Drills with an angle of 27 to 45 degrees have a shorter spiral band.

The drill bit has a normal spiral bar with an angle of 19 to 40 degrees.

Features of spiral drill

They do not need to be sharpened. These drills with high speed and power perform the work of drilling and chipping the surface.

Grinding drills does not change the diameter of twist drills.

These drills deliver coolant very quickly to the drill tip.

A twist drill easily guides chips out of the sides of the drill bit.

Twist drills create little friction with the surface.

They are easy to work with and even if you are not a professional you can easily pierce the surface.

The price of these drills is cheaper compared to other types of drills and they are very efficient.

Twist drill feature

What parts does the drill consist of?

The drill has two parts, body and shank. Each section has different parts that we will get to know later.

body

The body is the part on which the grooves are placed. Threads or grooves are intended for better chip removal.

leg

This part is connected to the body and is used to connect the drill to three drill systems. The shank is located along the axis of the drill. The shape of the leg is usually conical and straight.

neck

This part is located between the body and the leg. All the specifications of the drill are usually written on this part.

back edge

The back edge is in the form of a narrow groove that is aligned with the outer edge. This part maintains the alignment of the drill.

sharp edge or point

At the time of starting drilling, it determines the main location of the hole and guides the chips towards the cutting edges.

cutting edges

Two edges that are the same size and have the same angle and are located around the body.

Side in the drill

The back part of the cutting edges is called side.

level

In the grooves, there is a part that is placed next to the edges. This part is called the surface.

tip angle

An angle of 118 degrees that is aligned with the axis and the surface. The harder the surface, the higher the angle of the twist drill.

Spiral angle

The twist angle is actually the angle between the edge and the axis of the drill.

Different parts of the drill bit

CH

Choice of low-twist and high-twist drill

Low-torque drills are effective for better guiding of the chips and preventing the chips from getting stuck in the drill groove. The diameter of the grooves in the low twist drill is slightly larger than that of normal drills. There is no need to apply much pressure when working with this drill. They easily pierce the surface and generate less heat than other drills.

Twist drills produce more cutting slopes and are suitable for drilling metals such as aluminum and compressed plastics.

What is a multi-diameter drill?

Up to this part of the article, we talked about the same size drills in the leg and the body. But it is better to know that there are drills that have different diameters in different parts. These steps are separated by steep shoulders.

What materials are drills made of?

Each drill is used for one application. For this reason, the types of drills are different. In the following, we will examine some of the components of the drill together.

Low carbon steel drill

This drill is used for drilling holes in wood. It does not need to be sharpened and it does not have a retaining edge. It has a higher price than other drills and its lifespan is high.

High carbon steel drill

As its name suggests, this drill is made of steel with a high carbon percentage. Due to heating and hard work on this drill, the steel shell of the drill is very strong. This type of drill is used for drilling holes in wood and metal. Although it is very resistant to high temperature, if it is exposed to too much heat, it becomes loose and the cutting edges become softer.

High speed steel

This spiral drill is widely used due to its great resistance to temperature changes. For this reason, they are used on surfaces that require high-speed drilling, such as metals and hardwoods.

Twist drill with cobalt steel

This drill is very resistant to high temperatures and is used for drilling in stainless steel and steel. The only thing to pay attention to in these drills is the fragility of the cobalt drill.

Click to know the difference between HSS and TCT drill.

Twist drill with cobalt steel

Different types of drills

Drills have different shapes according to the application. Together we see different types of drill. To learn about the types of drill and its use, read this article from Radiran website.

diamond head drill

An alloy known as diamond is used at the tip of this drill. This drill is used for drilling holes in construction materials. Never use a diamond drill for metal. Because it causes its head to melt and burn.

Cobalt drill

This durable drill is used for drilling in thick metals. Because cobalt does not burn at high temperatures.

wood drill

The wood drill has a sharp tip. Due to its appearance and structure, it is widely used for drilling wood.

metal drill

This drill is only used for metals such as aluminum, copper and zinc. If you use this drill for iron, the drill will melt. Cobalt alloy is not used in this drill.

leaf drill

A leaf drill is used for wood. But it drills wood with a larger volume than other wood drills.

Granite drill

The granite drill has a structure similar to the diamond drill. But it is a little harder than that and is used for cutting granite.

gas drill

Gazor drill is used to make hinges in cabinets and closets.

Conical drill

This drill is usually used for metals. The shank of the drill is slightly thinner than its body, and for this reason, larger holes can be created with this drill.

Aluminum drill

Aluminum drill, as the name suggests, is used to drill holes in aluminum. Its shape is designed in such a way that due to the deep grooves, the shavings are easily removed so that the shavings do not melt and do not interfere with the work.

Drill birdie

The shape of this drill is cylindrical and it is used for drilling at an angle of 60 degrees.

4-slot spiral drill

This drill is used for demolishing concrete and construction works.

Multi-slot twist drill

Drill 5 grooves

It is quite similar to the 4-slot drill, only it has more power to destroy the material.

rotary drill

Rotary drills are used to make circular holes. Click to view and buy a drill bit from Radiran website.

treasury

This drill is used for drilling holes in wood.

Conclusion

In this article, we introduced the spiral drill and its types. According to their applications, the types and shapes of drills are also different. Before buying, you can call the numbers on the site to get free advice from Radiran experts. All industrial and household tools such as drills and chamfers with the best quality are available on Radiran tools specialized site. we are waiting for you.